Defect detection and classification in weld radiographic images

| 11 of 13 | << First | < Previous | Next > | Last >> | Back to gallery |

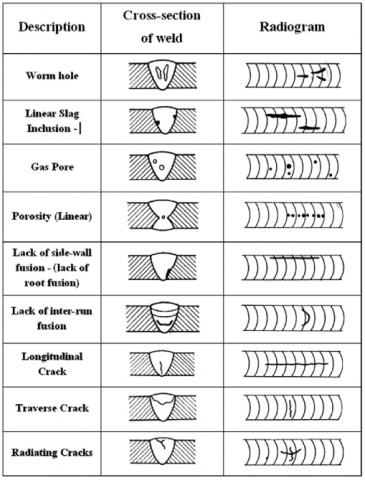

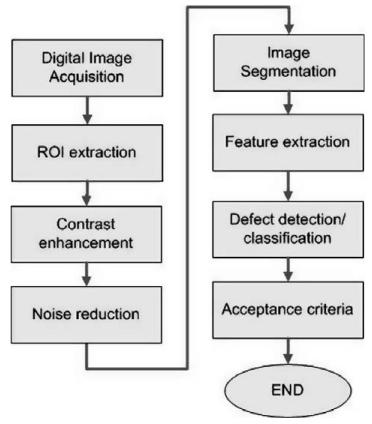

A method for the detection and classification of defects in weld radiographs was presented. The method has been applied for detecting and discriminating discontinuities in the weld images that may correspond to false alarms or defects such as worm holes, porosity, linear slag inclusion, gas pores, lack of fusion or crack. A set of 43 descriptors corresponding to texture measurements and geometrical features is extracted for each segmented object and given as input to a classifier. The classifier is trained to classify each of the objects it into one of the defect classes or characterize it as non-defect. Three fold cross validation was utilized and experimental results are reported for three different classifiers (Support Vector Machine, Neural Network, k-NN).

Related paper: